|

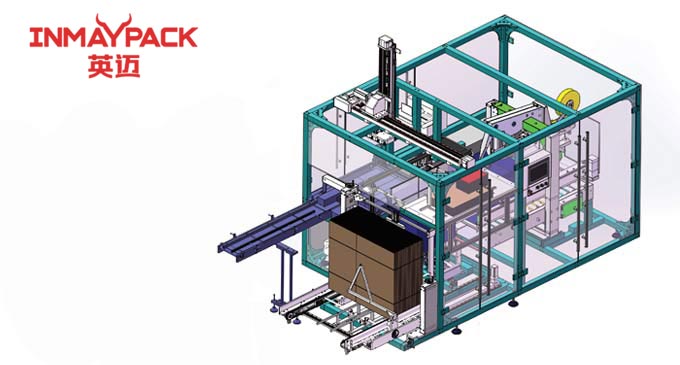

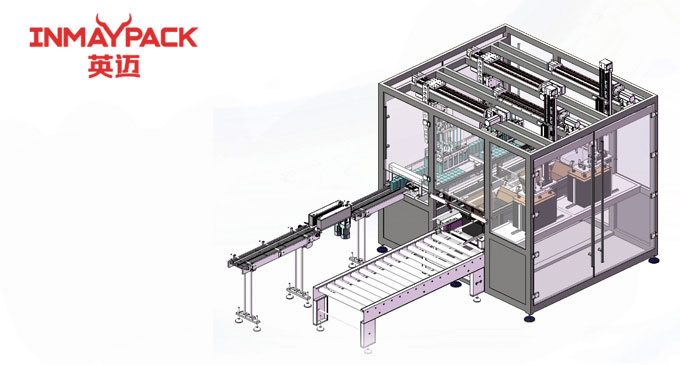

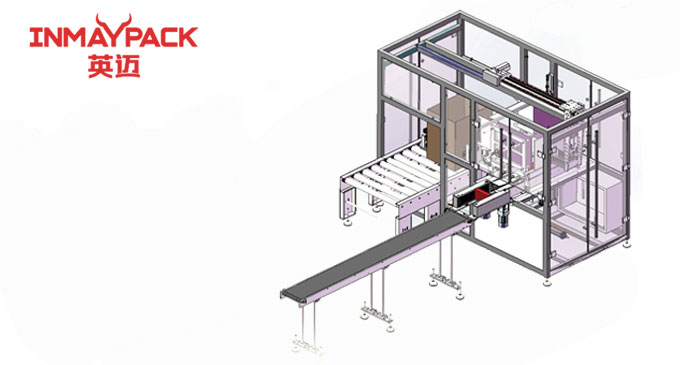

Equipment mode |

RM-600 |

|

Mini box size(mm) |

300X250X200 |

|

Max box size(mm) |

600X500X500 |

|

Weight |

3000(kg) |

|

Dimensions(L×W×H) |

240 |

|

Film size range |

5000*2000*2900mm |

|

Power supply |

7.5KW |

Can sachet packaging machines handle different sizes and shapes of sachets?

What safety measures are taken in sachet packaging machines?

How do sachet packaging machines reduce waste?

What advancements have been made in sachet packaging machine technology?