SG210-450 Automated Pre Made Pouch Filler and Sealer is a standardized low-cost, high-speed pre-made pouch filling equipment. It has a large adjustment range and high cost-effectiveness without increasing costs as much as possible.

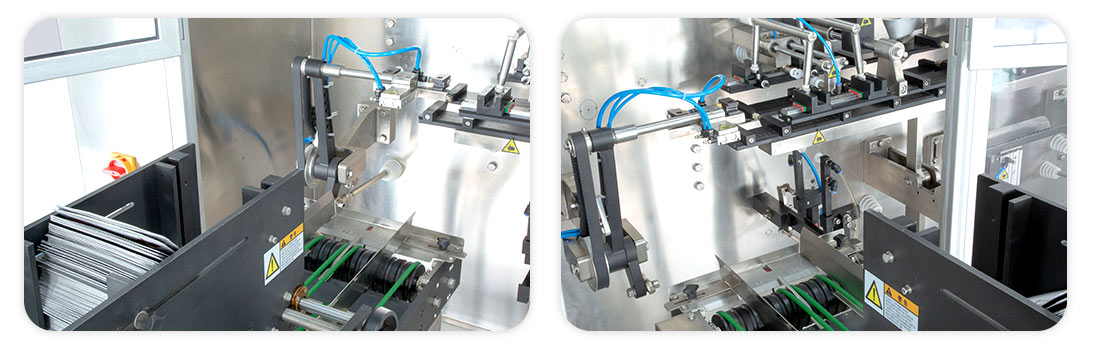

As a horizontal pre-made pouch packaging equipment, it can choose single-row or double-row working mode. When double-row bag making is selected, the machine can generate two small bags at the same time in each operation cycle, with a maximum speed of 100 bags/minute. To ensure high-speed packaging capabilities, the machine is equipped with two metering device stations, which can be expanded to four metering device stations at most, and can measure multiple materials once or multiple times.

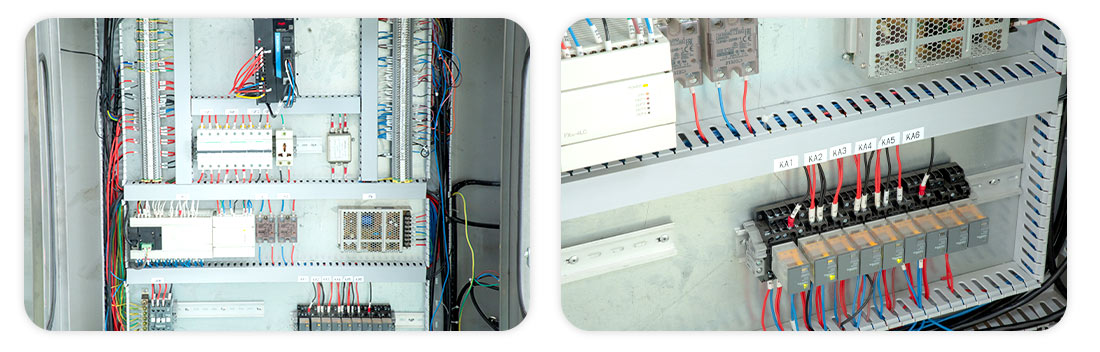

The equipment adopts an integrated cabinet and an independent 10-inch operation panel. The electrical control is integrated in the frame. The control system uses Inovance as a standard configuration, and brands such as Beckhoff or Alan Bradley can also be selected.

| model | SG210 | SG240 | SG330D | SG450D |

| Minimum bag size | 80×120 | 120×150 | 90+90×210 | 120+120×350 |

| Maximum bag size | 210×320 | 240×350 | 160+160×250 | 210+210×350 |

| Maximum bag volume | 1500ml | 2500ml | 750ml | 2000ml |

| Maximum production speed | 50 | 50 | 100 | 100 |

| Power consumption of equipment | 7.5Kw | 7.5Kw | 15Kw | 15Kw |