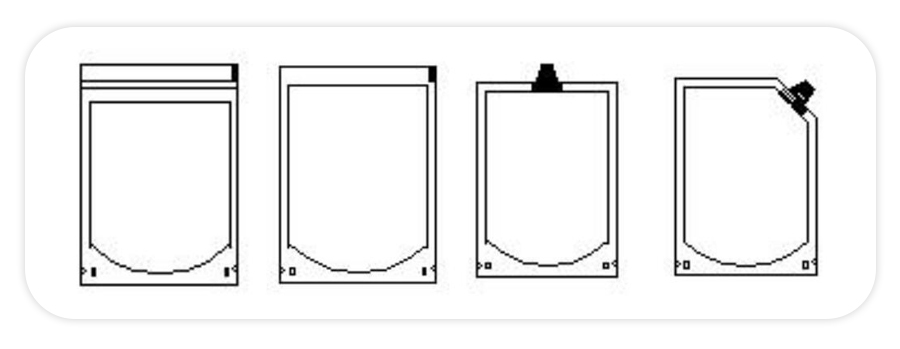

HMK1100-2000 Self-supporting Pouch Packaging Machine is a special equipment designed for small-capacity special-shaped bags. It is highly respected in the industry and is particularly suitable for high-speed packaging of beverage solutions, enzymes, collagen, etc. It can be equipped with a variety of filling equipment and film cutting molds according to needs to meet the unique production needs of different customers.

Equipped with two unloading stations, the equipment works in double-row mode. Two bags can be generated simultaneously in each operation cycle, and the speed can reach up to 120 bags/minute.

Optional metering methods such as servo plunger pump metering, pneumatic plunger pump metering, and gravity flow meter can be used to fill high-temperature materials at up to 92°. In view of the characteristics of high-temperature filling, three sets of bag mouth heat sealing systems with water cooling devices are used. The first step is to heat and weld the film, the second step is to continuously pressurize at low temperature, and the third step is to quickly cool down to make the bag mouth flat and beautiful.

It adopts an integrated cabinet and a separate film placing system. The film placing system has a servo film correction system, which can automatically correct the alignment position of the film after folding in half to avoid the impact of equipment shutdown adjustment on production capacity. The control system adopts Mitsubishi as standard, but Siemens, Alan Bradley or other brands are also available.

|

HMS-2000 |

||||

|

Machine operation |

HFFS |

Horizontal form fill and seal |

||

|

Technology concept |

Pouch origin |

Form the reel |

||

|

Pouch transport system |

intermittent |

|||

|

Construction |

Machine frame |

SUS304 apparance |

||

|

parts |

SUS304 and Aluminum Alloy |

|||

|

Parts in contact with product |

SUS316L /SUS304 |

|||

|

Reel |

Reel diameter |

600mm |

||

|

Reel Width |

720mm |

|||

|

Reel core |

76mm or 158mm |

|||

|

Machine dimensions |

Length×width×height |

57200×1150×2500mm |

||

|

Machine weight |

|

4000Kg |

||

|

Pouch dimensions |

Length×width×height |

|

Minimum size |

Maximum size |

|

Flat bag |

70×110mm |

210×320mm |

||

|

Doypack |

70×110×(22+22) |

210×320×(52+52) |

||

|

Packaging speed (pouches per minute) |

|

Speed maximum(ppm) |

Volume maximum(ml) |

|

|

Flat bag |

60 |

1000 |

||

|

Doypack |

60 |

2000 |

||

|

Consumption |

Electrical |

|

11kw |

|

|

Air consumption |

|

300L/min 0.6Mpa |

||

|

Electrical data |

|

|

200-415V/50-60Hz/N+G(According to customer requirements customization) |

|

| model |

HMK1100 |

HMK2000D |

HMK2000FED |

HMK2000YZD |

| Minimum bag size |

65×120×15 |

65+65×120×15 |

65+65×120×15 |

65+65×120×15 |

| Maximum bag size |

110×210×60 |

105+105×120×30 |

105+105×120×30 |

105+105×120×30 |

| Bag volume range |

300ml |

150ml |

150ml |

150ml |

| Production speed ppm |

60 |

80 |

120 |

100 |

| Film size range | Maximum diameter 500 mm, core diameter 76 mm | Prefabricated bag | ||

| Power consumption of equipment |

10Kw |

12Kw |

28Kw |

15Kw |