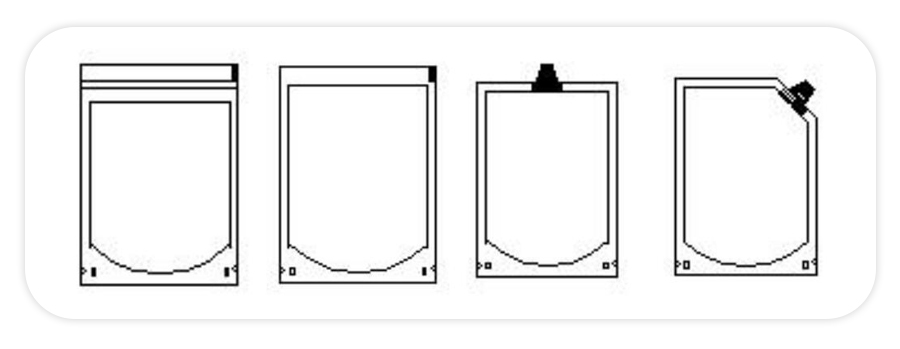

Doypack Ziplock Bag Packaging Machine (HMK-2000) has flexible packaging formats and can handle multiple types such as stand-up bags, bags with zipper closures, etc. The machine is equipped with advanced automatic filling, sealing and zipper sealing functions to ensure the tightness and convenience of each bag, so that the product can stay fresh for a long time.

PLC control and intuitive touch screen interface make operation simple and precise, and operators can easily set parameters and monitor the production process. These features make HMK-2000 the preferred equipment for high production efficiency and excellent packaging quality in various industries. It is an advanced equipment designed for modern packaging needs.

|

HMK-2000 |

||||

|

Machine operation |

HFFS |

Horizontal form fill and seal |

||

|

Technology concept |

Pouch origin |

Form the reel |

||

|

Pouch transport system |

intermittent |

|||

|

Construction |

Machine frame |

SUS304 apparance |

||

|

parts |

SUS304 and Aluminum Alloy |

|||

|

Parts in contact with product |

SUS316L /SUS304 |

|||

|

Reel |

Reel diameter |

600mm |

||

|

Reel Width |

720mm |

|||

|

Reel core |

76mm |

|||

|

Machine dimensions |

Length×width×height |

5720×1150×2500mm |

||

|

Machine weight |

|

4000Kgs |

||

|

Pouch dimensions |

Length×width×height |

|

Minimum size |

Maximum size |

|

Flat bag |

70×110mm |

210×320mm |

||

|

Doypack |

70×110×(22+22) |

21×320×(52+52) |

||

|

Packaging speed (pouches per minute) |

|

Speed maximum(ppm) |

Volume maximum(ml) |

|

|

Flat bag |

60 |

1000 |

||

|

Doypack |

60 |

2000 |

||

|

Consumption |

Electrical |

|

11kw |

|

|

Air consumption |

|

300L/min 0.6Mpa |

||

|

Electrical Data |

|

|

200-415V/50-60Hz/N+G (According to customer requirements customization) |

|