|

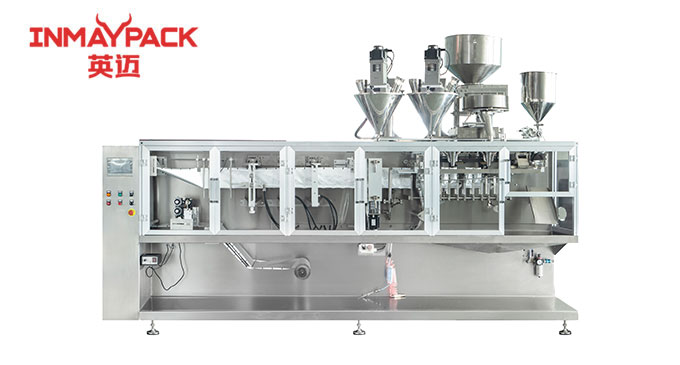

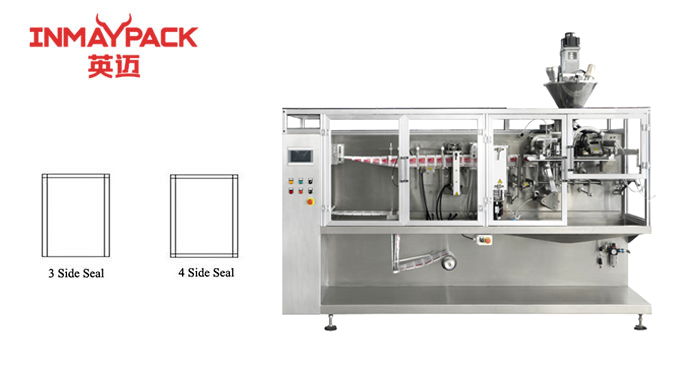

Equipment mode |

HS130 |

|

Mini bag size(mm) |

60×80 |

|

Max bag size(mm) |

140×200 |

|

Bag volume range |

100ml |

|

Production speed PPM |

80 |

|

Film size range |

Maximum diameter 350 mm, core diameter 76 mm |

|

Power Consumption |

6.5KW |

How to maintain a Flat Pouch Packaging Machine?

What Pouch Packaging Machinesindustries is it commonly used in?

What are its main features?

How does it operate?