|

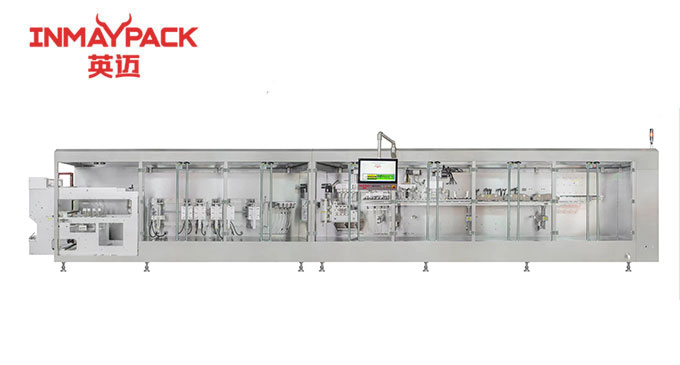

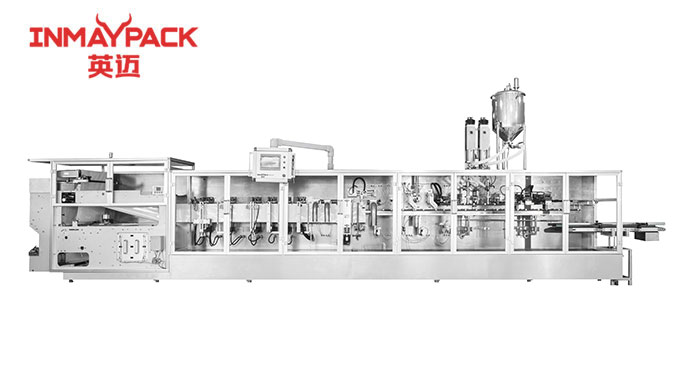

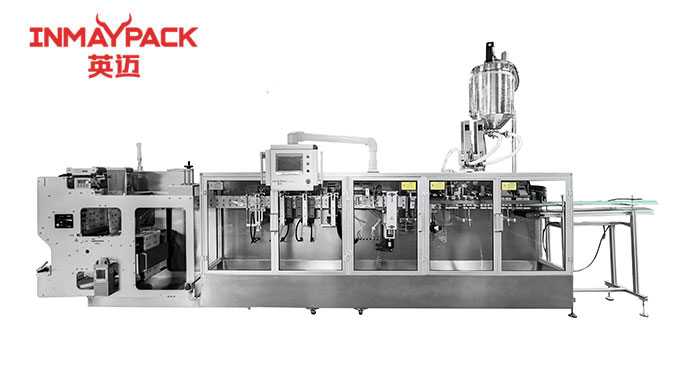

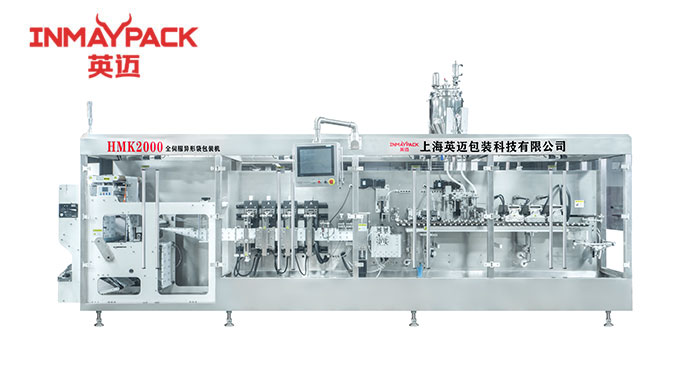

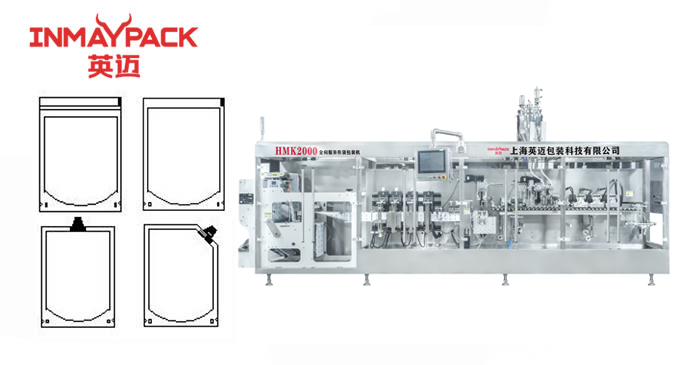

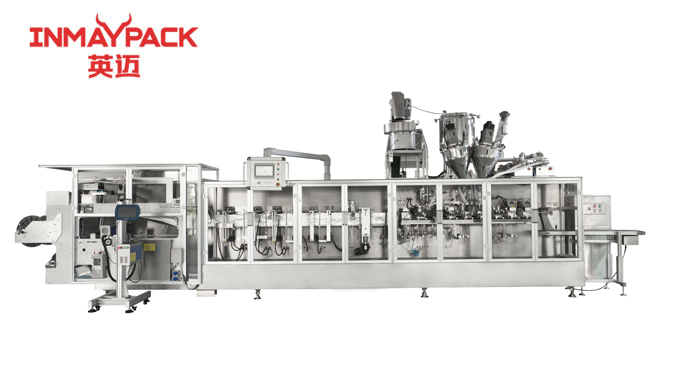

Equipment mode |

HMS320 |

|

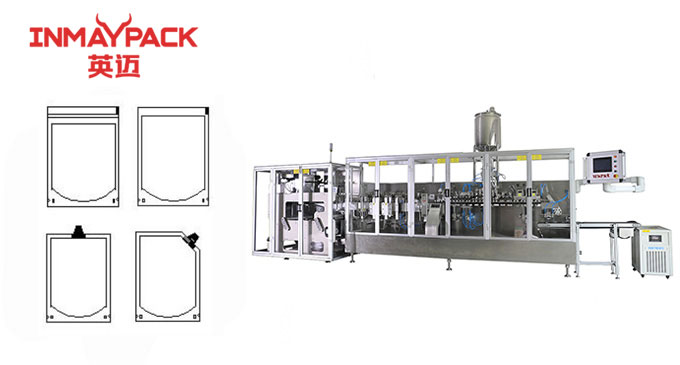

Mini bag size(mm) |

105*210*35 |

|

Max bag size(mm) |

320*300*60 |

|

Bag volume range |

3000ml |

|

Filling station |

4 working stations |

|

Power Consumption |

45KW |

What types of bags can a Doypack Packaging Machine handle?

What materials can be packed using a Doypack Packaging Machine?

How does a Doypack Packaging Machine ensure packaging quality?

How does a Doypack Packaging Machine address common packaging problems?