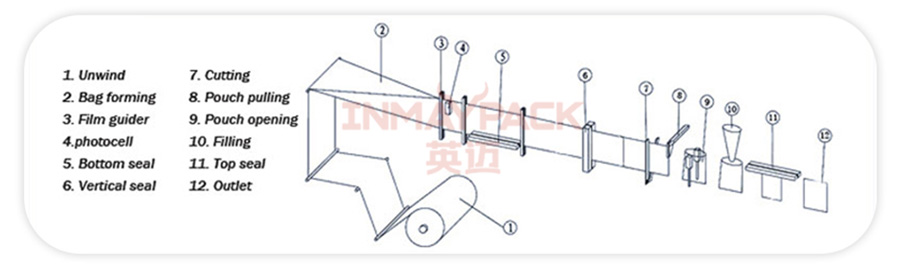

Three and Four Side Powder Flat Pouch Packaging Machine is a small horizontal forming, filling and sealing integrated packaging equipment. It is mainly used for small single-row bag making and filling, such as coffee powder, milk powder, sugar, and salt. The machine is also widely used in the packaging of creams, lotions, and hair wax in the cosmetics industry.

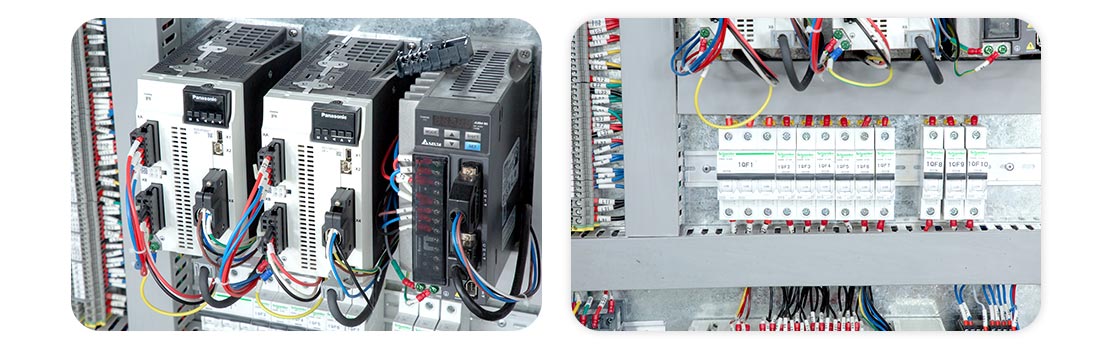

The equipment adopts an integrated cabinet and an independent operation panel, and the electrical control is integrated in the frame. The control system adopts Mitsubishi as the standard, and brands such as Siemens can also be selected.

1. Mainframe Frequency Conversion System: Imported AC motor and frequency conversion, stable and reliable operation; low speed and large torque ensure excellent performance even under sharp fluctuations of load.

2. Servo Blanking System: Panasonic servo motor controls rotation of blanking bolt directly by pulse number; stable and reliable performance,convenience of regulation.

3. Package Making System: The package making and sealing and filling systems are independent to each other in this system. The two systems are linked and coordinated by mechanical coupling and programmable logic controller (PLC). Therefore, the system is suitable for a variety of products and sizes of package.

4. Finished Product Sealing System: Fully automatic production facility that finishes package making, metering, filling, sealing and other packaging processes by heat-sealing packaging material (polyethylene membrane, multilayer composite membrane etc.). The package shall be three-side or four-side sealed flat package. Fillers of different types may package a variety of products.

5. Integrated Control System: It is composed of PLC, frequency converter etc., featuring a high level of integration, strong control capabilities and high reliability of operation. Touch screen technology eases and facilities operation. The optoelectric transducer,encoder, proximity switch etc. are all equipped with imported and advanced sensing elements, so the mechanical and electricalintegration of the entire frame is embodied perfectly.

|

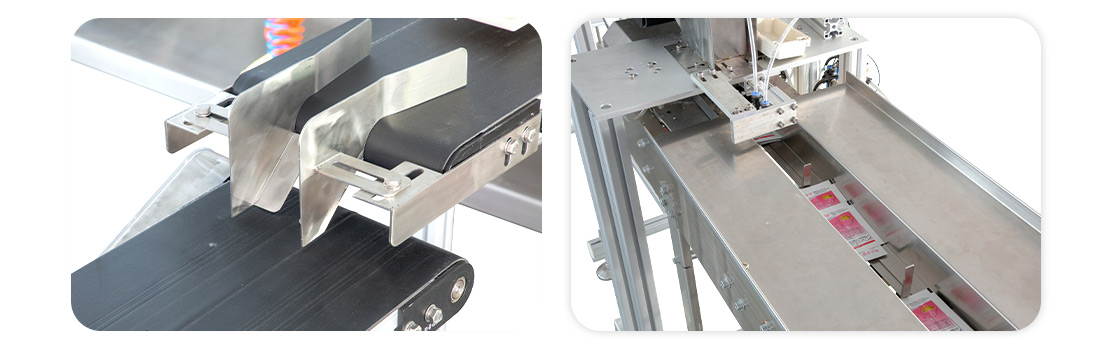

Machine operation |

HFFS |

Horizontal form fill and seal,three and four side sachet pouch packaging machine |

|

Technology concept |

Pouch origin |

Form the reel |

|

Pouch transport system |

intermittent |

|

|

Reel |

Reel diameter |

400mm |

|

Reel Width |

260mm |

|

|

Reel core |

76mm |

|

|

Filling stations |

|

1 (with 1 heads) |

|

Construction |

Machine frame |

Stainless steel SUS304/ Carbon steel, the surface plastic coating |

|

Except internal mechanisms |

Parts painted Stainless steel colour/Stainless steel SUS304,and Aluminum alloy |

|

|

Parts in contact with product |

Stainless steel SUS316L |

|

|

Machine dimensions |

Length×width×height |

2850×970×1250mm |

|

Machine weight |

|

1000Kg |

|

Pouch dimensions |

Length×width×height |

Minimum:60mm×80mm |

|

Maximum: 140mm×180mm |

||

|

Packaging speed |

|

Maximum:60ppm |

|

Pouch volume |

|

Maximum:160ml |

|

Consumption |

Electrical |

5.0kw |

|

Air consumption |

20L/min 0.6Mpa |

|

|

Electrical Data |

|

200-415V/50-60Hz/N+G(According to customer requirements customization) |

|

Equipment mode |

HS130 |

HS130TS |

HS160 |

HS160D |

|

Mini bag size(mm) |

60×80 |

60×80 |

60*80 |

60+60×80 |

|

Max bag size(mm) |

140×200 |

140×200 |

180*200 |

90+90×180 |

|

Bag volume range |

100ml |

100ml |

400ml |

200ml |

|

Production speed PPM |

80 |

50 |

80 |

100 |

|

Film size range |

Maximum diameter 350 mm, core diameter 76 mm |

|||

|

Power Consumption |

6.5KW |

7.5KW |

8.0KW |

8.5KW |