In food, beverage, and daily chemical industries, high-demand packaging often involves challenges like sudden order surges or long production shifts—requiring equipment that balances speed, quality, and minimal interruptions. Many businesses wonder: what makes a Doypack Packaging Machine stand out in such scenarios? This article answers that by focusing on the machine's core product features tailored to real-world production needs.

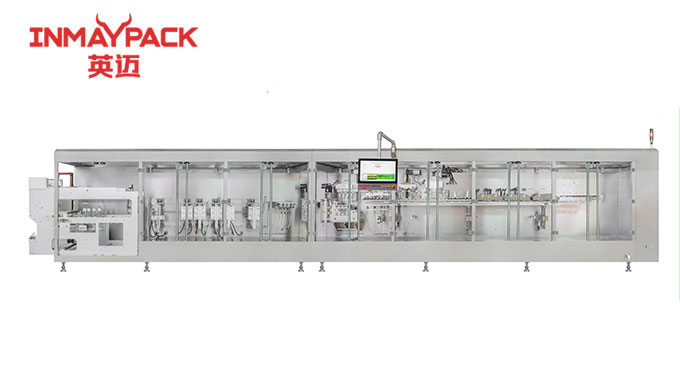

High-demand scenarios frequently call for 24/7 production, so equipment durability is non-negotiable. A Doypack Packaging Machine adopts a European-style stable structure, using high-grade industrial materials that resist wear over time.

This design reduces vibration and component strain during long hours of running, lowering the need for frequent maintenance pauses. Unlike less sturdy alternatives that break down easily under continuous use, its solid build seamlessly keeps up with the steady rhythm of high-output lines.

For products like snacks, powdered drinks, or liquid detergents, airtight seals are essential—even when production speeds are high. The Doypack Packaging Machine integrates multi-sealing units with a dedicated water-cooling system.

The multi-sealing units create uniform, tight closures, while the water-cooling system prevents heat buildup that can warp seals or damage packaging materials. This combination ensures every package meets strict quality standards, even when the machine runs at peak speed—eliminating wasted products or costly rework.

High demand rarely means fixed production: volumes fluctuate, and bag style needs often change (from standard stand-up pouches to premium zippered versions that enhance consumer convenience). A Doypack Packaging Machine supports both single-lane and multi-lane operation, plus accommodates various Doypack bag designs.

Switch to multi-lane for peak orders to boost output, or single-lane for smaller batches to save energy and reduce material waste. It also transitions between bag styles without time-consuming mechanical overhauls—eliminating the need for multiple specialized machines.

Filling speed is often a bottleneck in high-demand lines, as slow or inconsistent filling can disrupt the entire packaging process. A Doypack Packaging Machine comes with up to four filling nozzles, each featuring precise flow control to ensure consistent fill levels across every bag.

These nozzles work simultaneously to fill multiple bags at once, cutting down total production time while maintaining accuracy. Unlike single-nozzle machines that create bottlenecks, this design keeps filling perfectly in sync with sealing and bag-forming—ensuring smooth, fast throughput even during peak hours.

A Doypack Packaging Machine excels in high-demand scenarios thanks to its durable, material-rich structure, wear-resistant sealing system, flexible operation for varied needs, and precise multi-nozzle filling—all solving core pain points of busy production lines.

To explore how this Doypack Packaging Machine aligns with your specific output goals, bag type requirements, or efficiency targets, visit our product page for detailed specifications and custom solution inquiries.