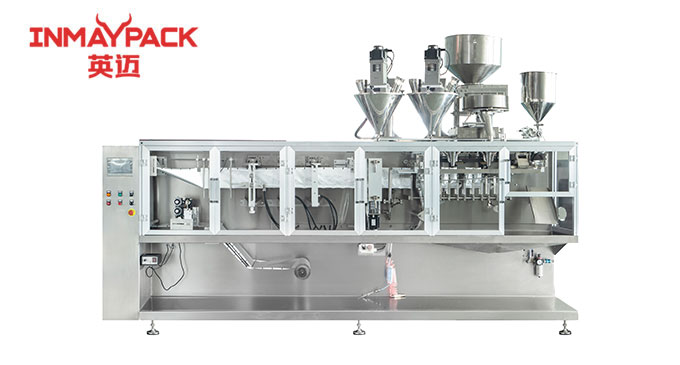

Many manufacturers ask a critical question: Can a single Flat Pouch Packaging Machine handle three distinct material types—granules, powders, and liquids—without needing separate equipment? The answer is yes, but it depends on specific design features that address the unique needs of each material. Below are key capabilities that make this multi-material compatibility possible, all rooted in proven equipment functions.

The foundation of multi-material use lies in the machine’s modular design, which lets operators swap core components to match different materials:

For granules (e.g., nuts, cereal): A dedicated feeding module with adjustable flow gates prevents jamming—wider gates for larger granules (like almonds) and narrower ones for small grains (like quinoa) ensure steady, even delivery to pouches.

For powders (e.g., protein powder, flour): A specialized powder module with a closed hopper and anti-dust seal reduces airborne powder, while a gentle vibration function breaks up clumps to maintain consistent filling volume.

For liquids (e.g., sauces, syrups): A liquid-specific module with anti-drip nozzles and precision dosing controls stops leakage—thick liquids (like honey) use heated nozzles to keep fluidity, while thin liquids (like vinegar) use slow-release valves to avoid splashing.

These modules connect via standardized ports, so swapping between them takes minimal time—no full machine disassembly, just quick component changes to switch from one material to another.

The machine’s recipe storage function eliminates the need to reconfigure parameters every time you switch materials:

Operators can save pre-set settings for each material type, including filling volume, pouch size, and sealing timing. For example, a “granule recipe” might have faster conveyor speed to match the feeding module’s output, while a “powder recipe” uses slower speed to reduce dust.

When switching from, say, granules to liquids, you simply select the saved “liquid recipe” instead of manually adjusting dozens of settings. This cuts downtime between batches and ensures consistency—even new operators can switch materials accurately.

A large color HMI (human-machine interface) paired with a PLC control system (such as Siemens or Mitsubishi) simplifies multi-material management:

The HMI uses clear, material-specific icons (e.g., a grain symbol for granules, a drop for liquids) to guide operation, so operators can easily identify and select the right settings.

The PLC system cross-checks settings with the installed module—if you select a “powder recipe” but have a liquid module attached, it triggers a warning to prevent mispackaging. It also adjusts real-time operations, like slowing the sealing process for liquids to let contents settle before closing the pouch.

A single Flat Pouch Packaging Machine can absolutely handle granules, powders, and liquids—thanks to modular design (for material-specific components), recipe storage (for fast setting swaps), and HMI + PLC control (for precise, error-free operation). These features let you streamline production without investing in multiple machines.

To see how this works for your specific materials—whether you’re packaging cereal, protein powder, or sauce—visit our product page. You’ll find details on module options, recipe storage capacity, and real examples of multi-material packaging in action.